Most die-hard baseball fans are well aware that Rawlings has been the official and exclusive supplier of baseballs for Major League Baseball for over a quarter-century. They may even know that each Rawlings Official Major League Baseball (ROMLB) is made in Costa Rica. But what most baseball enthusiasts might not know is the extreme scrutiny and the barrage of tests and inspections that every baseball must go through before they ever reach the pitcher’s mound of MLB ballparks across the country and Canada.

But Rawlings hasn’t always been the official ball of Major League Baseball. In fact, they are a relative newcomer to the game.

The first major league baseballs were manufactured by A. G. Spalding & Bros. in 1890 for the newly created National League. In 1892 the American Association of Professional Base Ball Clubs (later renamed the American League) was created and began using baseballs manufactured by A. J. Reach – a rival sporting goods company. Wanting uniformity in the two leagues, Albert Spalding, who was a pitcher and the manager of the Chicago White Stockings (yes, those White Stockings) bought out A. J. Reach Sporting Goods Company and began manufacturing baseballs for both leagues – with the National League using balls with the Spalding logo on them and the American League using balls with the Reach logo on them. This would continue for the next 85 years.

In 1955 Spalding bought out Rawlings Sporting Goods Company and turned over all baseball manufacturing to them. However, because of a long-standing exclusive naming agreement with the National League, Rawlings continued to stamp the Spalding logo on National League balls and the Reach logo on American League balls.

Even though this 1974 National League ball has a Spalding logo on it, it was manufactured by Rawlings.

In 1968 Spalding became the target of an anti-trust investigation and was forced to sell the Rawlings portion of its sporting goods company. However, because of a contractual agreement between the two sporting goods giants, Rawlings continued to stamp the balls with the Spalding and Reach logos – for nine more years.

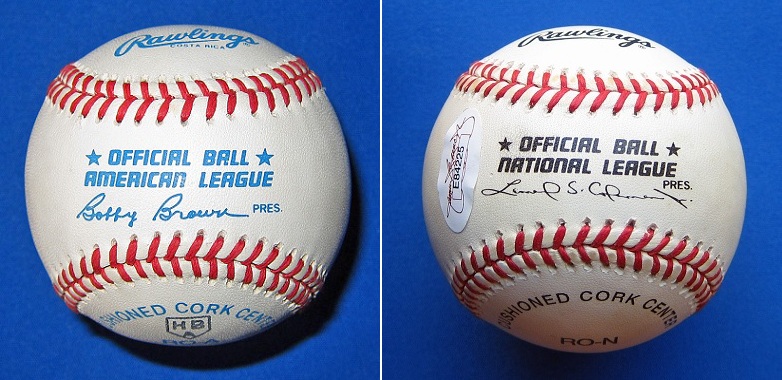

In 1977 Spalding’s exclusive National League naming agreement expired and Rawlings cut ties with Spalding and began using their own trademark logo on both American League and National League baseballs. Although identical in every other way, each league’s ball had their own league logo with their respective president’s name stamped on them. The American League balls were stamped in blue ink and National League balls in black ink.

Even though Rawlings did not stamp their logo on baseballs until 1977 when they were named the official ball of Major League Baseball, they had actually been manufacturing baseballs for both leagues since 1955.

Rawlings has been the official ball of Major League Baseball since 1977 but the actual ball since 1955.

Up until 1987 all Rawlings baseballs were manufactured in Haiti, but sensing political instability in the small island country, Rawlings opened a second factory in the friendly Central America country of Costa Rica. This move proved to be a wise one for Rawlings, as increasing political tension forced Rawlings to shut down their Haiti factory in 1990 and allowed the Costa Rica factory to continue manufacturing baseballs without interruption.

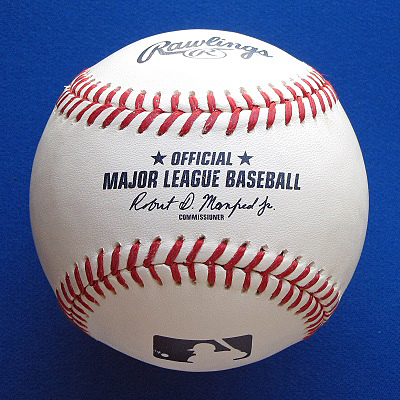

In 2000 Major League Baseball did away with individual league presidents, thus giving full governing authority over both leagues to the commissioner of baseball. At this same time, the MLB also did away with league-specific baseballs (even though they were the exact same ball but with separate league markings) and went with a single identical logo for both leagues – thus the ROMLB was born.

Rawlings now produces 80,000 dozen ROMLBs annually at its Costa Rica plant – this not counting baseballs made exclusively for the World Series, the All-Star Game and other special events such as the World Baseball Classic, etc.

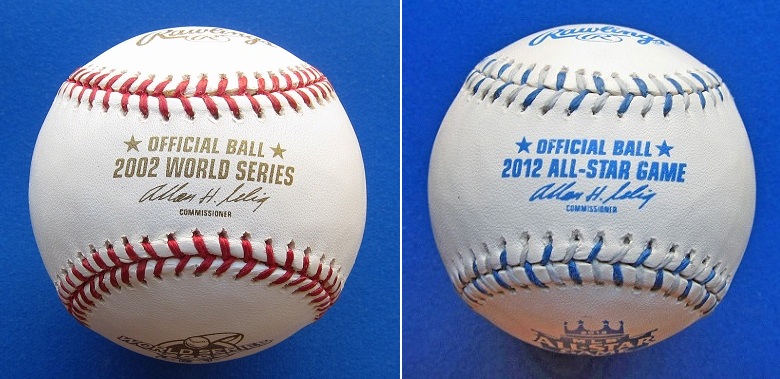

Rawlings makes event-specific balls for the World Series, the All-Star Game, (including the Home Run Derby), the World Baseball Classic and other special events.

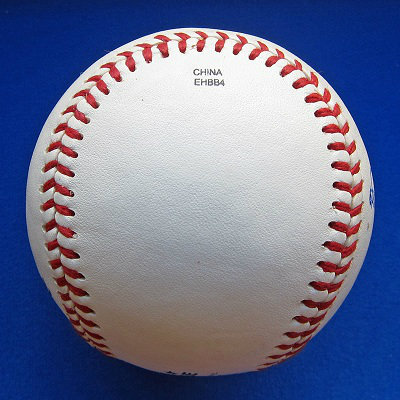

Rawlings also makes all official Minor League baseballs, but do so at a factory located in China. Unlike the Major League balls made in Costa Rica, the Minor League balls include a stamp indicating that they are made in China. This is probably due to some type of trade agreement between China and the United States.

Rawlings Official Minor League Baseballs very closely resemble their Major League counterparts but are manufactured in China.

MLB’s strict specifications for the manufacturing of each ROMLB calls for a cork center (called a “pill”) that is wrapped in two thin rubber layers and weights exactly 7/8 oz. This pill is then machine-wound under consistent tension with 121 yards of four-ply blue-gray wool yarn, 45 yards of three-ply white wool yarn, 53 more yards of three-ply blue-gray wool yarn, and 150 yards of fine white poly-wool blend yarn. When finished, the yarn-covered ball (called a “center”) is coated with an adhesive and two separate pieces of elongated figure-8-shaped white cowhide covers are placed on it. Once the covers are applied to the center, they are double stitched together by hand using 88 inches of 10/5 red cotton thread. It takes approximately 10 minutes to hand sew the 108 stitches into each baseball, with the first and last stitches completely hidden. Once stitched, the ball is machine rolled for 15 seconds to assure that the newly sewed seams are flat and even. The balls are then stamped with the Rawlings trademark, the MLB logo, and the commissioner’s signature and allowed to dry for a week. When finished, each ROMLB must weigh between 5.0 and 5.25 oz and be within a tolerance of 2.86 to 2.94 inches in diameter and 9 to 9.25 inches in circumference.

Although ROMLBs are manufactured in Costa Rica, the cowhide for the covers actually comes from the United States and is closely inspected for 17 different defects such as stretch marks, tick bites, barbwire marks, etc. and is tested for tensile strength. It is then sent to the Tennessee Tanning Company in Tullahoma, TN where it is alum tanned (which gives it its bright white color) and then shipped to Costa Rica.

But wait… there’s more!

Completed balls are then inspected for weight and diameter to confirm that they meet the strict MLB specifications and several balls from each shipment are randomly selected and shot from an air cannon at 85 feet per second against a wall made of northern white ash (the same wood used to make baseball bats). Each tested ball must bounce back between 0.514 and 0.578 of its original speed to be suitable for MLB use. The balls are then shipped to the U.S. where they are again inspected by weight and diameter. ROMLBs that make the cut are then sent to each of the 30 MLB teams for game use and those that do not are sold on the retail market (for collectors and autograph seekers, etc.) or sold to MLB teams at a reduced price to be used for batting practice balls or for promotional purposes.

But wait… there’s still more!

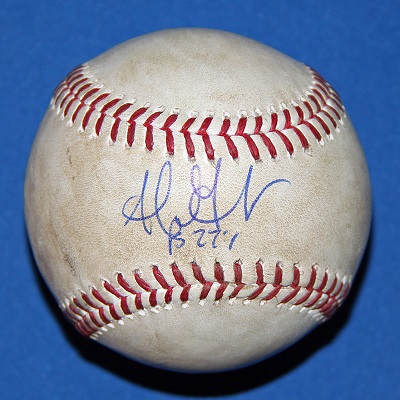

Once an MLB team receives its shipment of ROMLBs, each ball is hand rubbed with a special mud that comes from a remote (and secret) stretch of the Delaware River in New Jersey. It is this mud that gives each game-used ROMLB its off-white and slightly darkened color – almost dirty looking (go figure).

It’s pretty easy to spot a game used ball because of the Delaware River mud that has been rubbed onto it.

Rubbing mud onto the balls removes the ball’s slick, shiny outer coating, allowing pitchers to have a better grip and more control. It also dulls the bright white sheen on them which, if not done, gives a distinct advantage to hitters. Hitters, on the other hand, will sometimes argue that a ball with too much mud is too dark and makes it difficult to see (and hit). This is why umpiring crews closely examine each and every mud-rubbed baseball (for consistency) in the umpire’s room prior to every MLB game.

* * * * * *

Ball Trivia

- Eight to twelve dozen baseballs are used in a typical Major League game.

- The average life of a baseball in the Majors is 6 pitches.

- Each team uses approximately 144 baseballs during batting practices

- The terms “live ball” and “dead ball” have been applied to baseballs for more than 100 years. In the early years of the game, the home team was expected to provide the game balls and a good hitting team would wind their baseballs tightly for a lively (live ball) effect, while a good defensive team would wind their baseballs looser for a softer (dead ball) effect.

- In 1857 the length of a game was set at nine innings and pitching was done “underarm” (underhand) from a distance of 45 feet and the batter was out if a fielder caught the ball on the first bounce.

- In 1978 Rawlings began manufacturing the commemorative ROMLB World Series game baseballs with distinctive trademarked logos. Rawlings continues to manufacture these event-specific baseballs for three years following the actual event.

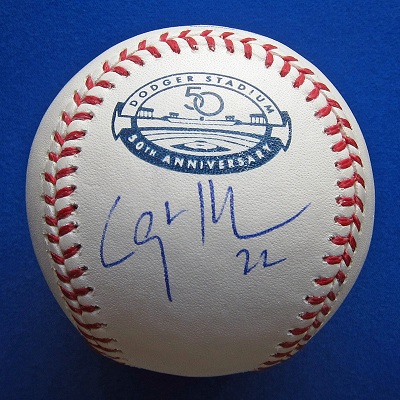

- Since 1983 Rawlings has been manufacturing special commemorative ROMLBs for events such inaugural stadium openings, franchise or stadium anniversaries (such as the 60th anniversary of Dodger Stadium), and other milestone events such as Derek Jeter’s 2,000th hit, to name just a few.

PLAY BALL!

* * * * * * * * * * * *

(Article updated and re-posted from June 22, 2015)

August 7th, 2018 at 8:00 am

August 7th, 2018 at 8:00 am  by Ron Cervenka

by Ron Cervenka

Posted in

Posted in

Nice article, I wasn’t aware of all these changes.